Cleaning Services for Safety, Efficiency, Sustainability & Compliance

USA DeBusk meets the cleaning needs of power generating plants with industrial cleaning services that deliver not only operational and cost efficiencies, but also enhanced safety, environmental protection, and regulatory compliance.

We offer proven solutions for all types of facilities, both union and non-union, including steam, cogeneration, and nuclear.

Outage support features include:

Cost tracking and daily spend updates

Pre-shift and post-shift outage meetings with progress reports

Safety Manager and certified confined space rescue teams

Site-specific health and safety plans

Versatile equipment, including pumps up to 2,500 hp that are easily convertible to meet the flows and pressures required for air preheater, economizer and boiler cleaning

Applications & Services

Vertical/Primary elements and economizer

Precipitator and hopper cleaning

Tubular style air preheater cleaning

Rotating air preheater (RAPH) cleaning

Stationary air preheater cleaning

Scrubber cleaning

Selective catalytic reduction (SCR) cleaning

Boiler washing/furnace cleaning

Exchanger/condenser brushing and scraping

Economizer cleaning

Exchanger/condenser cleaning

On-line boiler clinker deslagging

Cooling tower basin cleaning

Camera inspection

Complete decommissioning services

Online hydro blasting

Online vacuum services

Custom chemical cleaning with circulation for boiler tubes & steam condensers

Vacuum services

Hydro blasting

Tank cleaning

Safety

Safety is our first priority, from initial planning through outage completion.

We develop a project-specific safety plan that includes both customer and USA DeBusk guidelines. Our processes incorporate automated technologies to reduce risks to personnel.

Our safety culture extends throughout the organization, with active participation from senior management. Each project has a dedicated safety manager and certified confined space rescue team.

Safety trackable QR codes on each USA DeBusk employee’s ID badge links to cloud-based records of certifications and training, allowing customers to check the status of any employee in real time.

Service Highlights

Our outage solutions include these advanced technologies and services.

Vertical/Primary Elements and Economizer

Water-driven BJV heads

10,000 psi, 605 to 2,500 hp pumps

50 to 300 gpm

Cable across boiler

Automation protects employees and and maximizes cleanliness

Precipitator & Hopper Cleaning

Correct fan spray firehose nozzles prevent electrode damage

Vacuum clear hoppers and hydro blast blockages

2-D head clean panels with hardened materials

Grit blast/dry clean precipitators

Ice blast wires/plates; dry method for electrical connections

Air Preheater Cleaning (Tubular Style)

Automated 2XLTC and 3XLTC

2-D nozzle cleaning

Various tube diameters and lengths

Automated technology improves cleaning efficiency and consistency for each tube

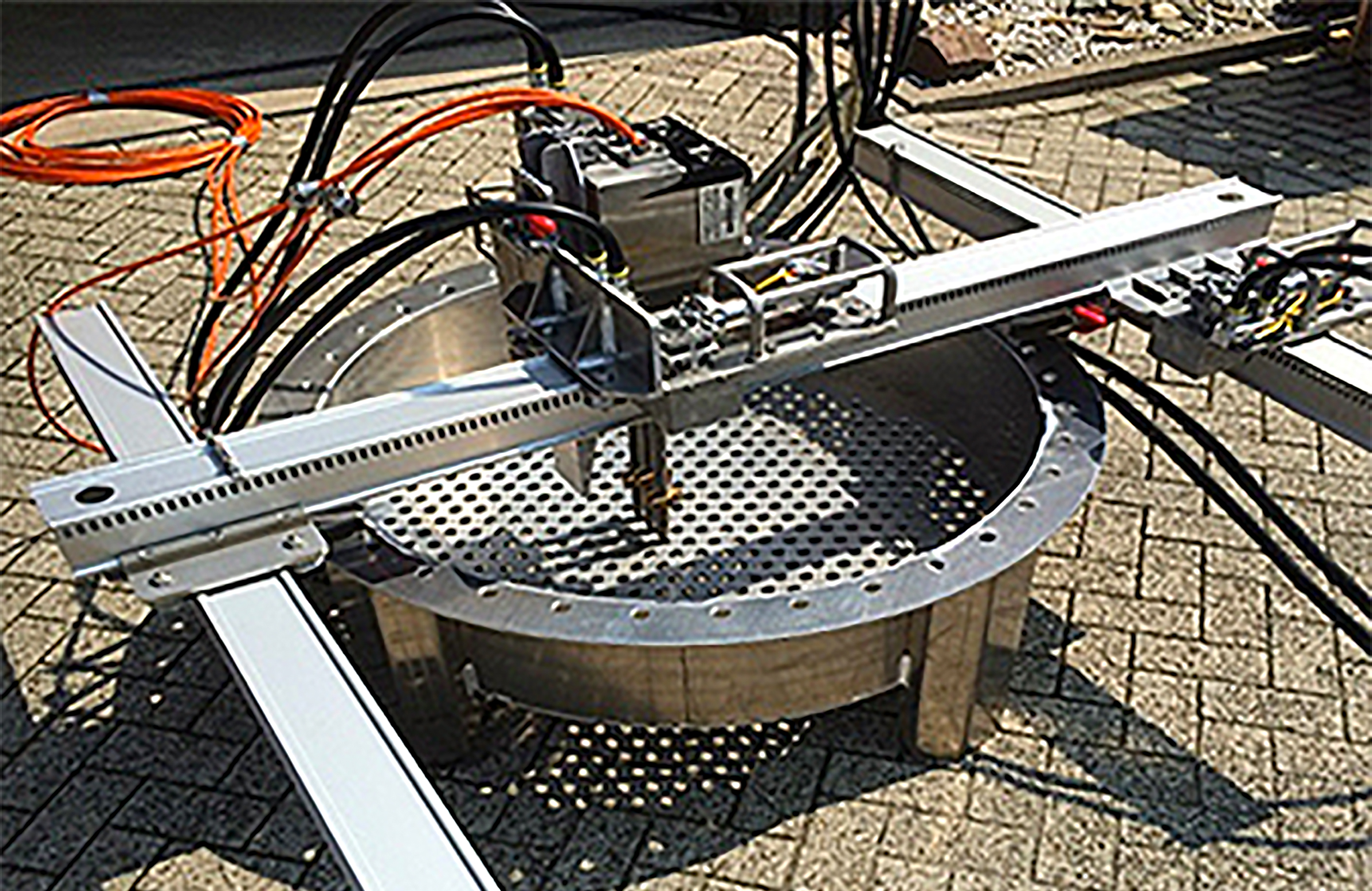

RAPH/Stationary APH Cleaning

Ljungstrom and Rothemule types

Automated technology improves cleaning efficiency and consistency

High volume (up to 100 gpm), low pressure (up to 3,000 psi)

Vacuum air heater tops and duct work post wash

Wash top down only needed

Hydro lance air heater drains

VSD for wheel rotational control

Run heads on both sides of APH for efficiency

Scrubber Cleaning (FDG Units)

Automated 2-D and 3-D hydro blast and vacuum absorber and recycle tanks

Hydro blast mist eliminator panels

Hydro blast cone room

Clean ring neck header

Clean sparger

Clean all stages of absorber internals, including nozzles

SCR Cleaning

Blow down all bulk from beams top level

Place plastic

Vacuum after screen removal

Vacuum after catalyst removal

Ice blast internals once catalyst is removed

Boiler Washing/Furnace Cleaning

10,000 psi, 605 to 2,250 hp pumps

50 to 300 gpm

Automated systems manage dwell times for heavy pluggage

Remove slag and debris from eyebrows, monkeys, wingwall, roof pendants, water walls, and downdraft

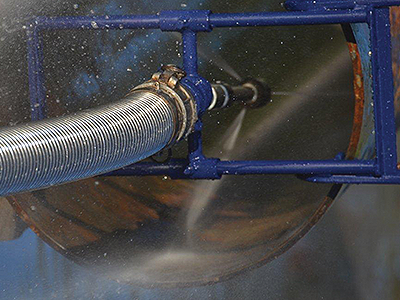

Evaporator/Condenser Cleaning

Variety of methodologies, including Stiff Lance, Flex Lance, Controlled-Volume Pigging, 2XLTC, and 3XLTC

Hands-free automated technology for safety, efficiency, and consistency