Solutions to Maximize Coker Productivity

USA DeBusk is a trusted provider of support services for coker operations, with specialized technologies and experienced rapid-response teams that deliver turnkey solutions. We offer a full suite of services to help coker operations remain productive in emergencies and reduce downtime during planned outages.

Jet pump temporary support

Specialty coker hydro blasting

Unit clearing & chemical cleaning

Online coke fines removal

Automated frac tower decoking

Line and pipe cleaning

Furnace coil pigging & decoking

Hydro cutting

Specialty Service Highlights

Our turnkey, multi-service line solutions for coker turnarounds include these advanced technologies.

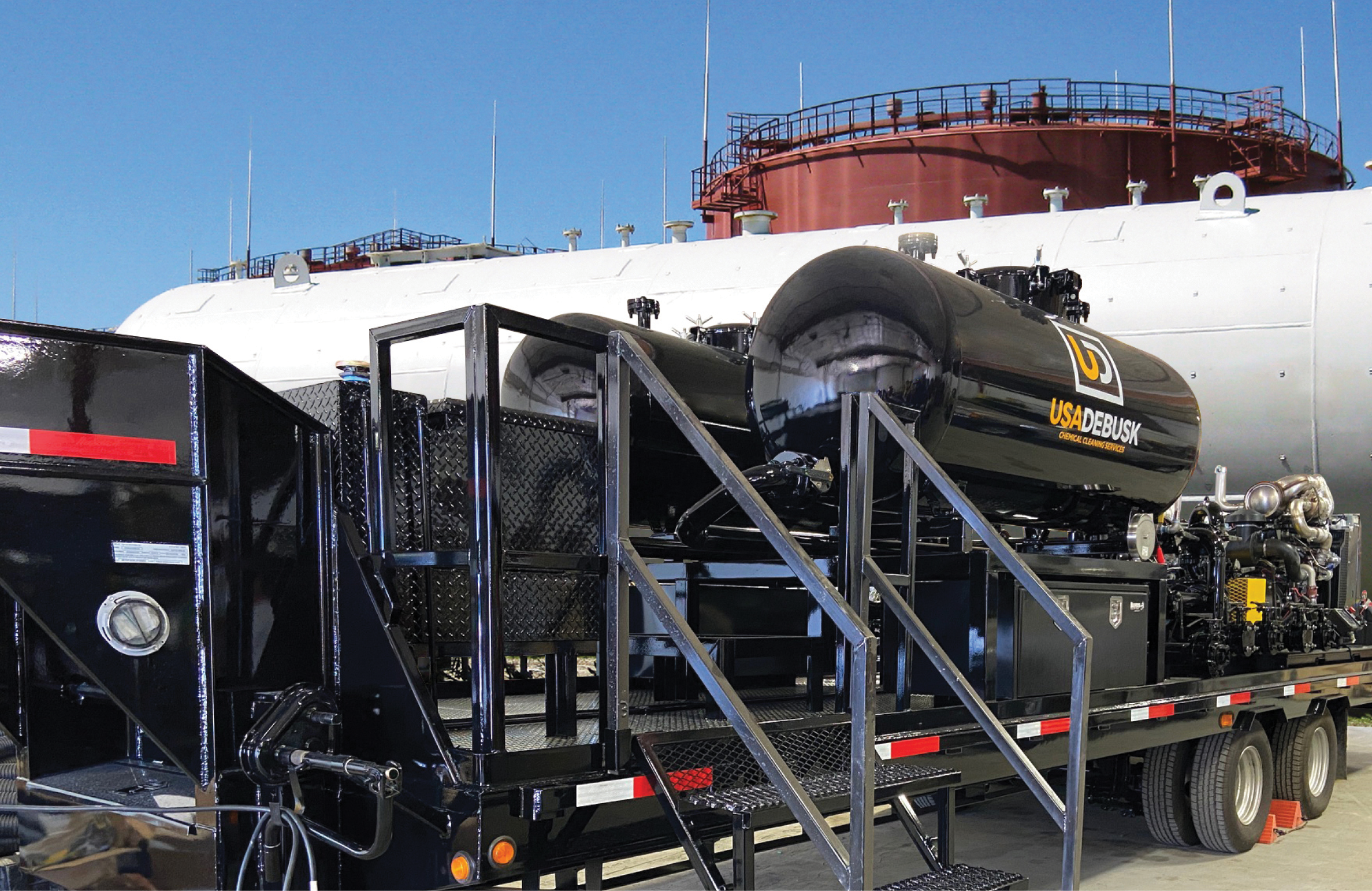

Jet Pump Temporary Support

Complete functional solutions to replace lost jet pump capacity. The service allows you to maintain productivity by cutting on normal cycles and for normal durations.

High-volume/high-pressure pumping units from 125 hp to 2,500 hp

Equipment packages are kept ready to deploy to your site 24 hours a day, 365 days a year

Computerized command center controls up to 20 pumping units

Flows/pressures/safety functions controlled via live camera/computer feed

Real-time camera/data feeds available to customers

Unit Clearing

A turnkey decontamination package using safe and effective cleaning products, experienced technical supervision, advanced equipment and innovative processes.

Opens the unit efficiently, saving days on the turnaround critical path

Safe for personnel and equipment

Pre-engineering to develop detail drawings and timelines

Proven, predictable results

Online Coke Fines Removal

The only solution in which free coke fines can be removed from coker processes while the unit remains online. These services effectively clean cutting/quench water between turnarounds, protecting jet pumps and pipes from abrasive damage. Automation and computer-assisted remote control completely eliminate personnel exposure during fines removal—all with video monitoring of processes.

Cleans weir pits, maze pits, cutting/quench water tanks, rail car trenches and sumps, clear water cutting pit sumps, coker clarification tanks

Zero employee exposure to hazardous conditions during removal processes

Minimum 95% faster than conventional methods

Eliminates the need for isolation blinding, fresh air requirements or vessel entry permits

Effective for standalone online cleaning or as part of outage projects

Pigging, Decoking & Filtration

Mechanical cleaning of furnace coils to restore flow and heat exchange efficiency while reducing differential pressure. Includes comprehensive project design, engineering, scheduling, cost savings analyses and results verification.

World’s largest fleet of TriMax™ triple pumping systems that increase productivity by 50%

Advanced electronic controls, automation and video monitoring

The industry’s most diverse selection of decoking pigs

Closed-loop effluent filtration

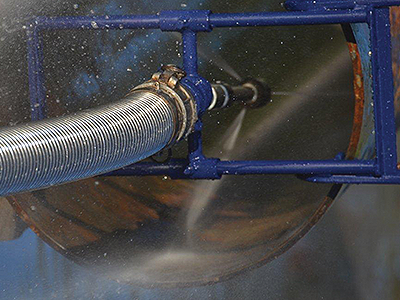

Specialty Line Cleaning

Industry-leading technology to clean vapor lines, transfer lines and lines associated with the heater.

Automation for safety and productivity

Custom engineering to apply properly sized hoses, nozzle configurations, pressures and cleaning speeds for each line

Containment of coke and water

Highly trained personnel

Coker Hydro Cutting

The safe, precise solution for piping, tower, and concrete cuts.

40,000 psi water

Fully automated operation

Specialty tracks

Dedicated hydro cutting teams