Pioneering Expertise, Innovative Technologies

From computerized, three-dimensionally controlled automated systems to expertly performed manual procedures, USA DeBusk has the versatility to apply the most effective technology for projects of any size or scope. All processes and equipment are engineered for operator safety, first-pass cleaning effectiveness, and speed of job completion.

USA DeBusk offers the latest automated technology and equipment, including hydro blasting units up to 40,000 psi (20 gpm) with pumps over 2,500 hp.

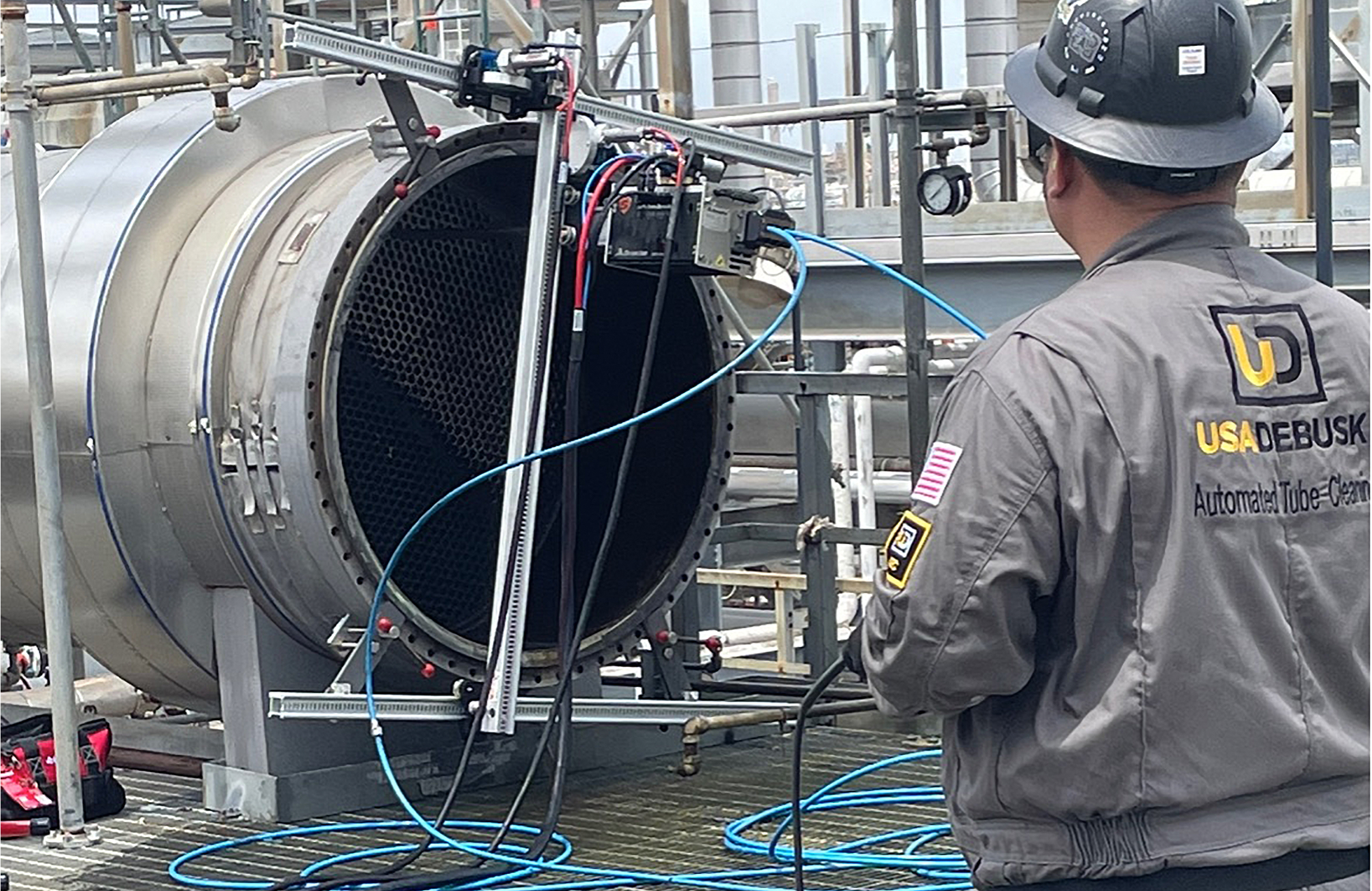

Automated Tube Cleaning

These systems use computerized applications to ensure the control of precise index locations and mechanically feed multiple flex lances into the tubes. Water pressures up to 40,000 psi to remove and eject foulants. Automation provides thorough, consistent cleaning and extended run times to complete projects with maximum efficiency.

ATL-5000 Tube Cleaning

Automated Flex Lancing

Shell Side Cleaning

The ATL-5000 bundle cleaning system allows a single operator to hydro blast tube bundles from a climate-controlled station located a safe distance away. A powerful hydraulic drive system enables the operator to control all movements of the system for speed and efficiency.

The system operates at pressures up to 20,000 psi and can be configured for various length bundles. With the addition of a roller control package, the operator can also manipulate rotation of the bundles. The ATL-5000 system is completely self-sufficient and requires no external power or air supply.

ATL-5000 Shell Side Cleaning

Tanks and Vessels

3-D Nozzle systems reduce cleaning costs by eliminating the need for scaffolding and increasing productivity with continuous, round-the-clock operation. A 3D nozzle can apply up to 150 gpm at 20,000 psi.

Piping

The system operates by rotating 360 degrees and continuously hugging the ID of the piping. A specially engineered nozzle remains forced against the wall and cuts the deposits while rotating. As the hose rotates, wheels allow it to move into the line and around multiple 90s. The rotary action and nozzle design are not only effective in removing debris, but also greatly reduce the amount of streaking that occurs with conventional hydro blasting.