Deep Cleaning Powered by Nanochemistry

Advanced NanoTech exchanger cleaning - only from USA DeBusk - offers a practical, cost-effective way to clean and recover the original design efficiency of shell-and-tube heat exchangers. This onsite, on-the-slab process restores exchanger R and U values to like-new condition by removing scale, paraffinic deposits, and asphaltenes down to a nanoscopic level.

NanoTech cleaning is effective with exchangers of all types and designs, as well as piping, fittings, and other components.

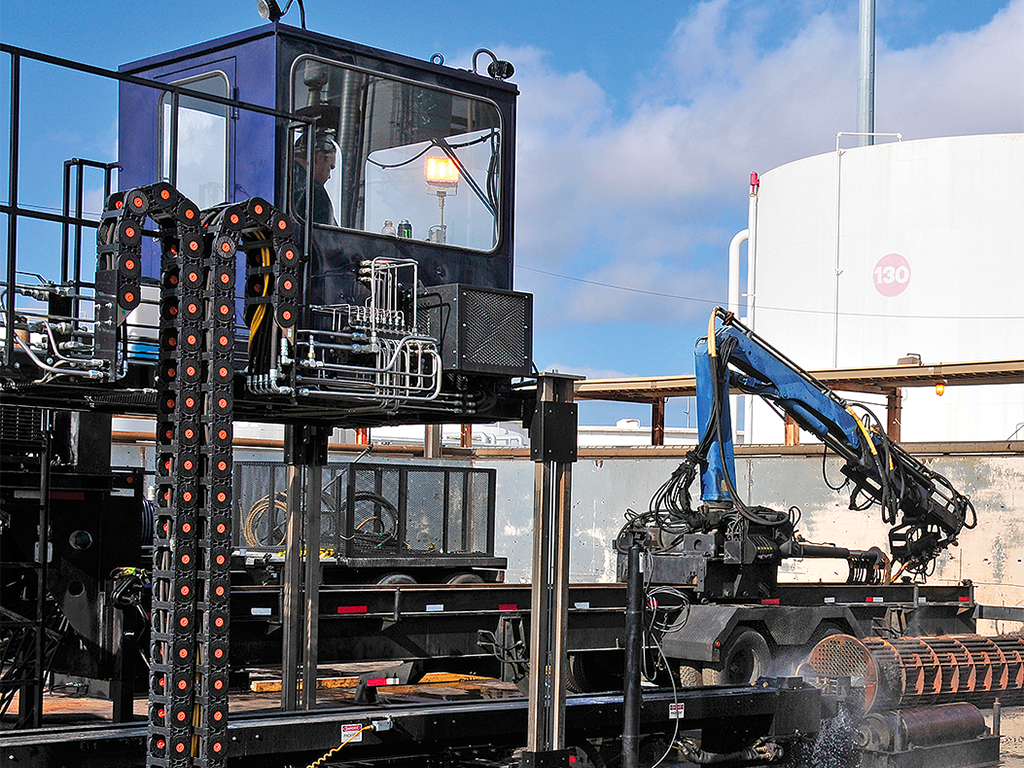

Automated shell and tube cleaning

A Complete Exchanger-Cleaning Solution

Cleaning begins with state-of-the-art automated hydro blasting of shell and tube sides, followed by immersion treatment in our patented nanochemistry solution.

The entire procedure is performed onsite, saving time and money while eliminating transportation and logistics issues with offsite cleaning.

The system is highly mobile and occupies minimal space for added convenience on the cleaning pad.

The NanoTech Process

USA DeBusk offers multiple hydro blasting techniques to remove visible debris from both the shell OD and tube ID. All systems are automated and hands-free, increasing efficiency and improving safety by keeping workers away from the blast zone.

During immersion treatment, exchanger bundles and other components are submerged in a purpose-built cleaning chamber filled with our proprietary nano fluid solution. Steam coils in the chamber add heat and an air co-injection system provides agitation to increase the cleaning action of the solution.

NanoTech cleaning of a typical exchanger requires only a few hours, based on project conditions.

Cleaning in NanoTech chamber

Nanochemistry penetrates to the microscopic level

Why NanoTech Cleaning is So Effective

Nanoscale technology is used in energy, electronics, healthcare, and other industries. It takes advantage of special properties of particles one-billionth of a meter in size—about 100,000 times smaller than the width of a human hair.

At this scale, NanoTech particles can penetrate deep into multiple layers of heavy fouling to break down deposits. NanoTech particles also have enhanced electrostatic force and constant thermal motion, which increase cleaning action by breaking away debris from metallic surfaces.

For like-new exchanger cleaning, NanoTach cleaning offers a full spectrum of speed, convenience, and cost-effectiveness.