Patented, Powerful Productivity

USA DeBusk’s patented VBX+ exchanger tube cleaning system provides the efficiency of high-precision, multi-nozzle automation, the safety of programmed remote control, and the one-pass polishing ability of advanced vapor blasting. VBX+ polishing is the industry's most advanced technology to restore heat transfer efficiency and prepare tubes for nondestructive testing (NDT).

Heat Exchanger Cleaning with VBX+ Polishing

A Higher Level of Cleaning

VBX+ exchanger polishing is an automated process that uses proprietary vapor blasting to clean the ID of heat exchanger tubing to bare metal. It is highly effective with both straight tube and U-bundle exchangers.

In vapor blasting, abrasive media is mixed with water, direct-injected under pneumatic pressure into an airstream, and discharged through triple-head injector nozzles.

The vapor and abrasive stream removes carbon, scale, and process contaminants, polishing the ID of tubes to bare metal and preparing them for Eddy Current inspection, Internal Rotary Inspection System (IRIS) inspection, or other nondestructive testing.

The VBX+ control system allows fine-tuning of flow rates and abrasive concentrations for optimum results. The process protects metallurgy as it removes contaminants.

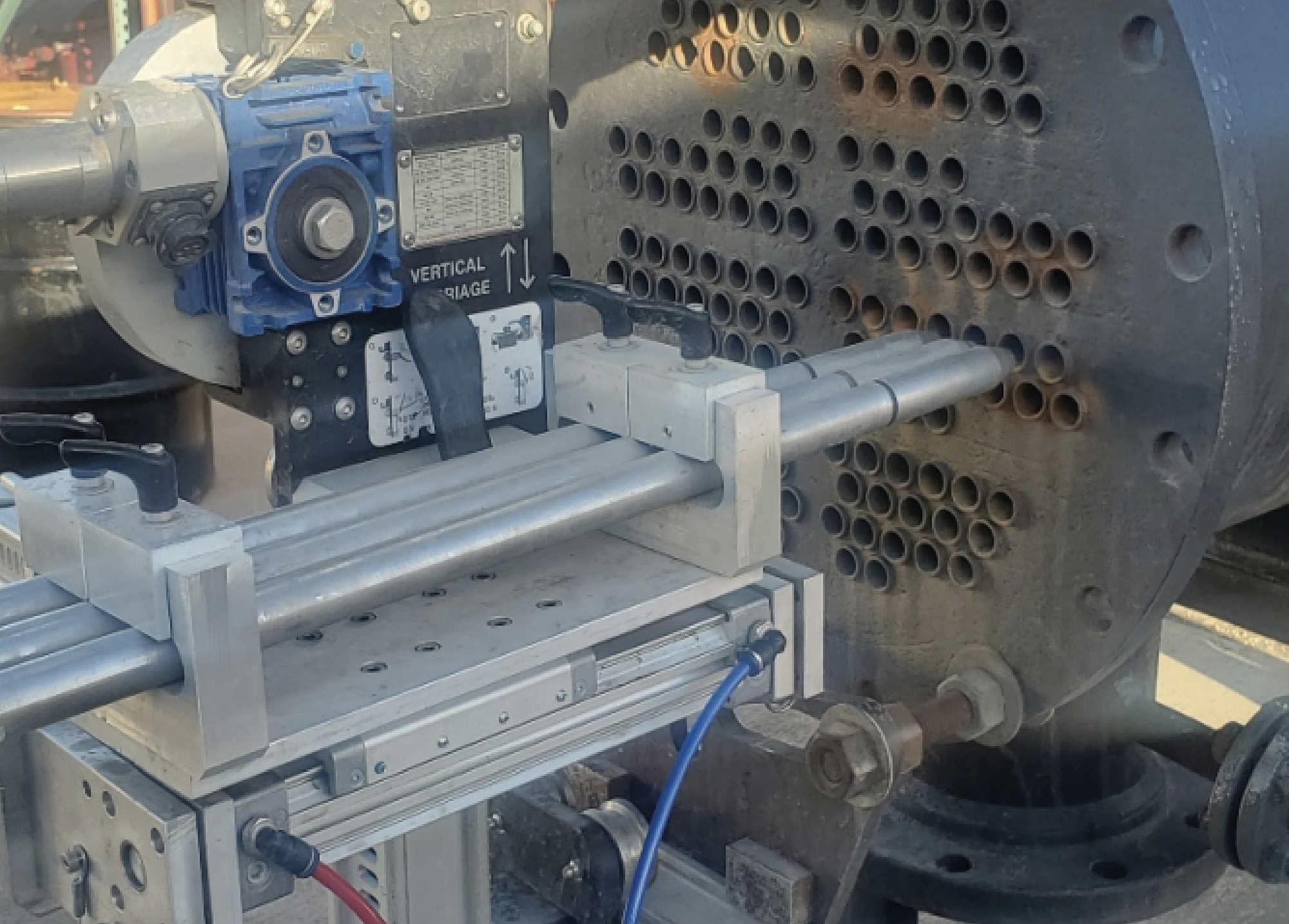

Automated, multi-nozzle vapor blasting

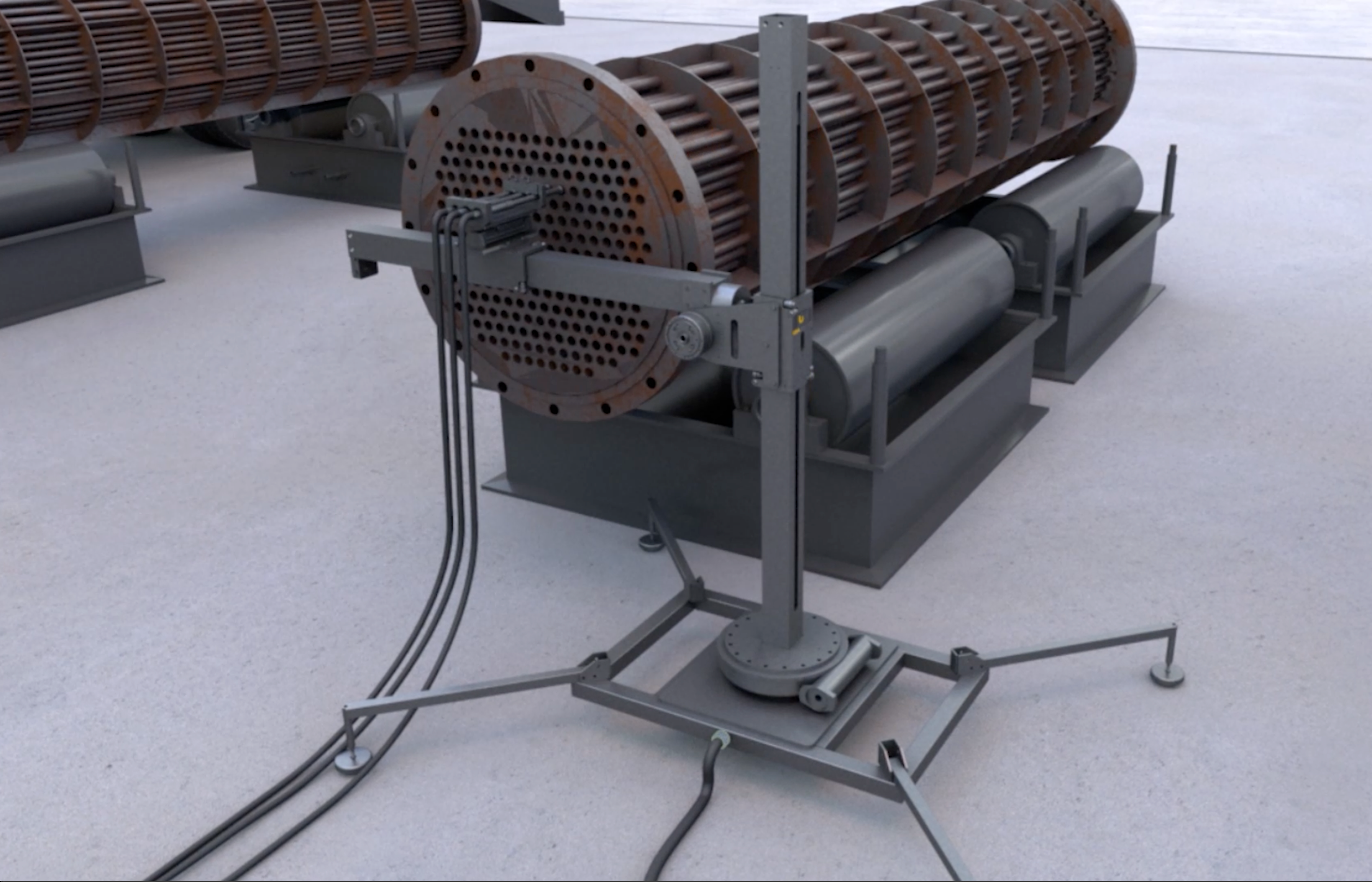

VBX+ systems are compact, mobile, and ideal for pad or CIP projects

Small Footprint, Big Impact

A VBX+ system consists of a water/abrasive mix pot, high-precision indexer, triple head with injection nozzles, and control system where a single operator oversees cleaning.

The system is compact, highly mobile, simple to set up, and safe for other nearby crafts. The process is fully automated, providing precise cleaning and high productivity.

VBX+ polishing can be used on the wash pad or in the unit (CIP).

Versatile & Effective

VBX+ cleaning yields better results in less time than standalone hydro blasting on both straight tube bundle and U-tube bundle heat exchangers.

The VBX+ system enables crews to quickly change vapor blasting media for optimal cleaning of all tube materials - from brass and stainless steel to carbon steel and other materials.

This is a significant advantage in speed and efficiency when multiple types of bundles are being cleaned.

Effective with a wide range of exchanger designs and tube materials