NDT Tube Inspection

Accurate, reliable exchanger tube inspection plays a critical role in reducing turnaround times, minimizing maintenance and repair costs, and getting plant processes back online.

USA DeBusk offers a unique, single-source solution by combining high-accuracy inspection and advanced tube cleaning as an integrated service.

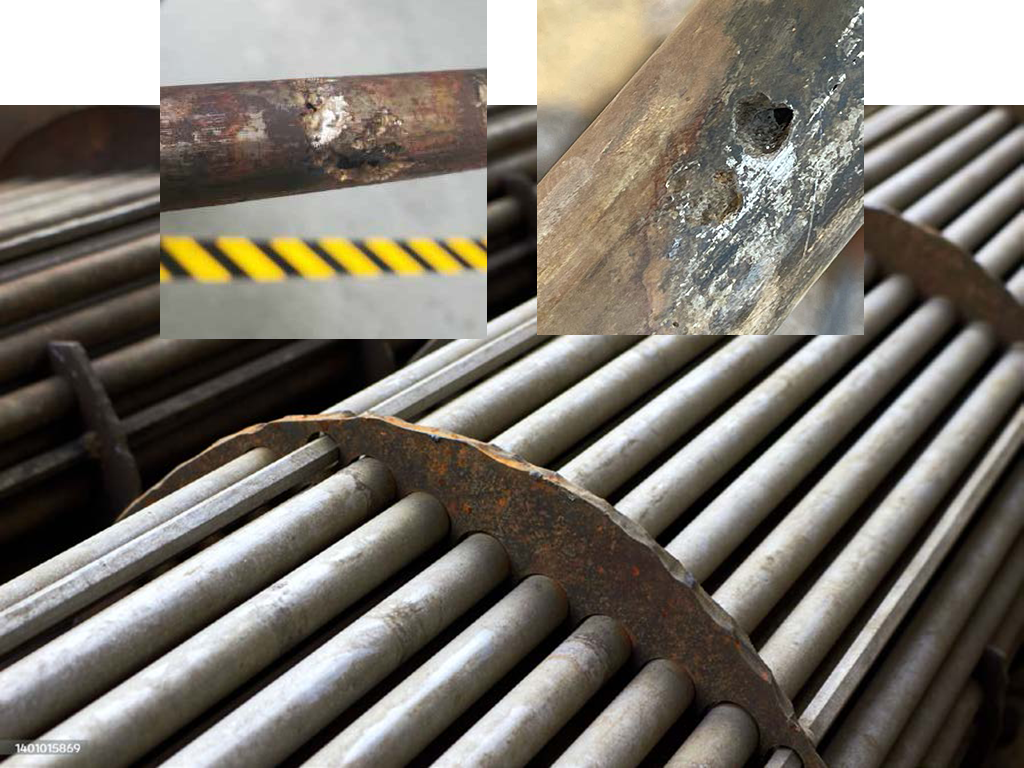

Anomalies detected

Inspection Capabilities

USA DeBusk offers veteran expertise and sophisticated nondestructive testing (NDT) techniques to inspect and assess the integrity of tubes in boilers, chillers, condensers, evaporators, and other processing equipment.

Our services establish baseline readings and determine integrity loss due to cracks, corrosion, pitting, tube wear, tube wall loss, and other flaws.

Our experts have the experience and insight to select the right technique to locate and characterize flaws, maximizing first pass accuracy for peak efficiency.

We employ only the latest, proven NDT inspection methodologies to assure compliance and meet your objectives.

NDT Methods

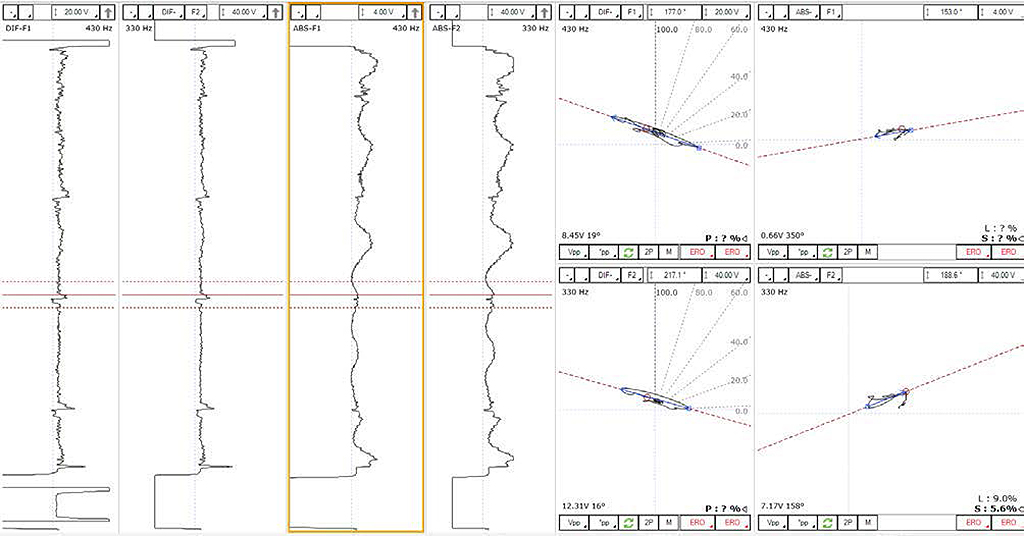

Eddy Current Testing (ECT)

ECT is used with nonferromagnetic materials. It is less sensitive to tube cleanliness than other methods. ECT has high detectability and speed, making it ideal for inspecting corrosion and wear over long distances.

Typically used for:

Exchanger tubes

Condenser tubes

Chiller tubes

Remote Field Testing (RFT)

RFT inspection is an electromagnetic technique for ferromagnetic materials, such as carbon steel, MONEL®, chromium-molybdenum (chrome moly), and nickel. It has nearly equal sensitivities of detection at the inner and outer surfaces and is highly sensitive to variations in wall thickness.

Typically used for:

Exchanger tubes

Boiler tubes

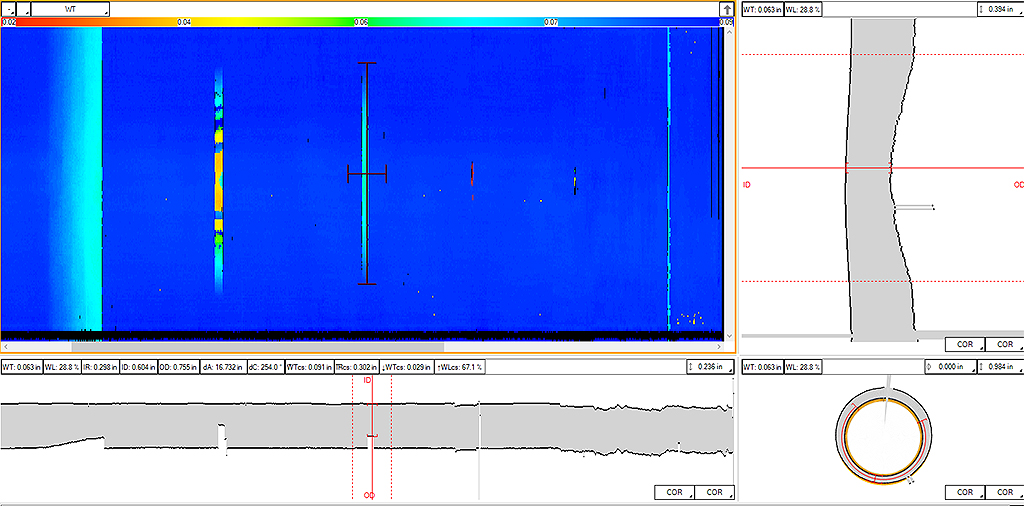

Internal Rotating Inspection System (IRIS)

Typically used with carbon steel and other ferromagnetic materials, IRIS uses sound to detect flaws or discontinuities within a tube. It is more sensitive to tube cleanliness than other methods, but produces highly accurate results, especially when detecting metal loss.

Typically used for:

Boiler tubes

Exchanger tubes

Fin-fan tubes

Near Field Testing (NFT)

NFT is an electromagnetic test used to inspect aluminum-sleeved tubes in fin fan coolers. It can also be used for testing carbon steel. It is a fast, cost-effective solution that is best suited for detecting internal corrosion, pitting, and erosion.

Typically used for:

Fin-fan tubes

ID inspection

Superior inspection methods

Automated Tube Cleaning (ATC) System

VBX+ tube polishing

Integrated Tube Cleaning

Tube cleaning capabilities can be seamlessly integrated with inspection for a highly efficient asset integrity solution. Combined cleaning/inspection improves efficiency, safety, turnaround time, and focus on achieving client objectives.

Automated Systems

Only USA DeBusk offers both conventional hydro blasting options and advanced systems with extensive automation and proprietary technologies.

Our Automated Tube Cleaning systems feature computerized, remote operation of the entire process for high productivity, while reducing the need for personnel in blast zones during cleaning.

Patented VBX+ exchanger polishing offers fully automated operation plus a proprietary vapor blasting process.

With this system, special abrasive media and water are direct-injected under pneumatic pressure into an airstream and discharged through triple-head injector nozzles.

Synergy & Value

For even greater value, inspection and cleaning can be combined with chemical cleaning, reactor cleaning, and a full portfolio of other USA DeBusk Services.