High-Value Services to Increase Safety & Efficiency

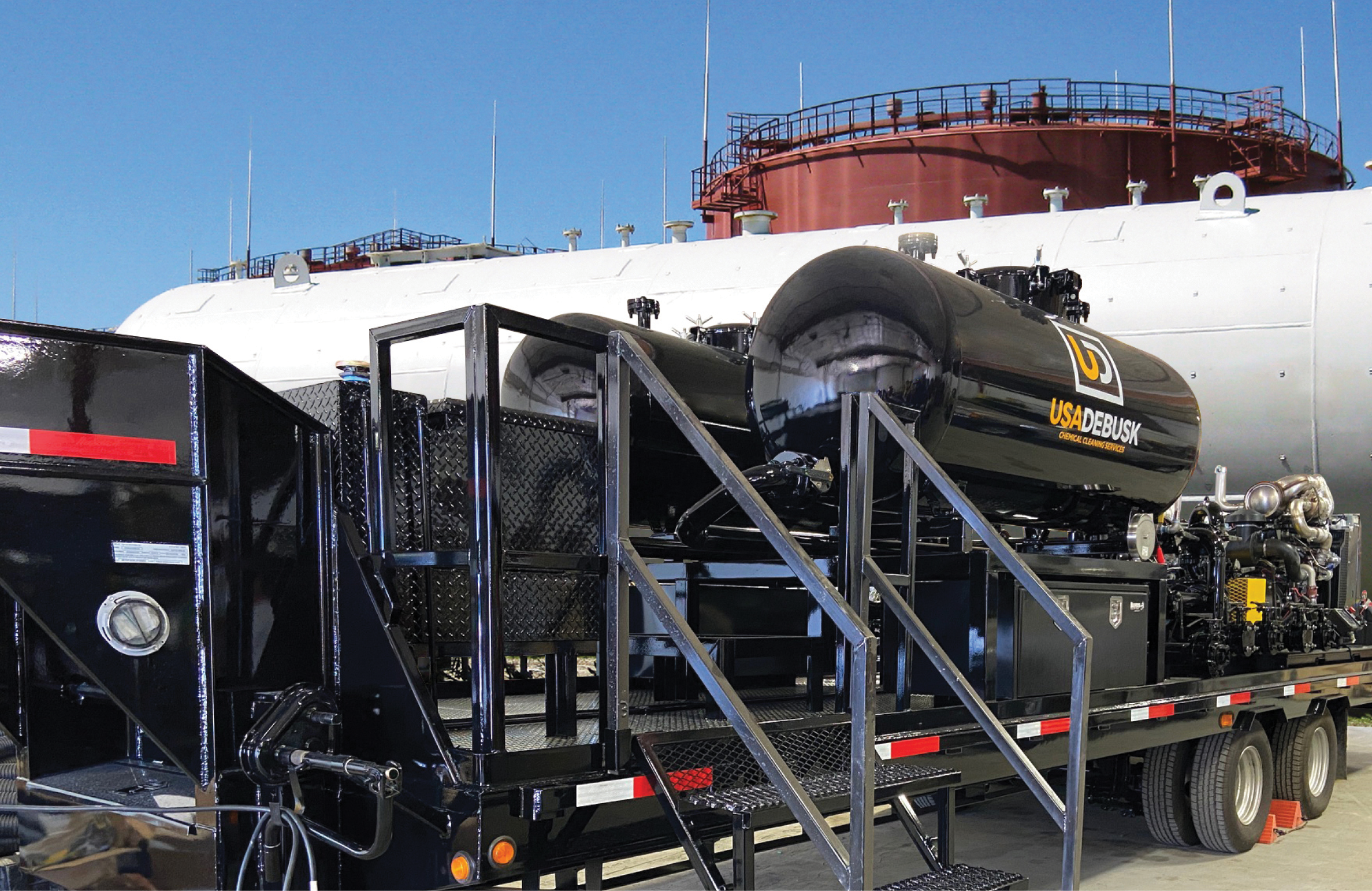

USA DeBusk offers total service capabilities for FCCU turnarounds, orchestrating multiple high-value services and technologies to add value at every phase of your turnaround.

Enhance safety

Reduce turnaround duration

Minimize handling damage

Reduce offsite exposure and transportation risks

Single point of contact and responsibility

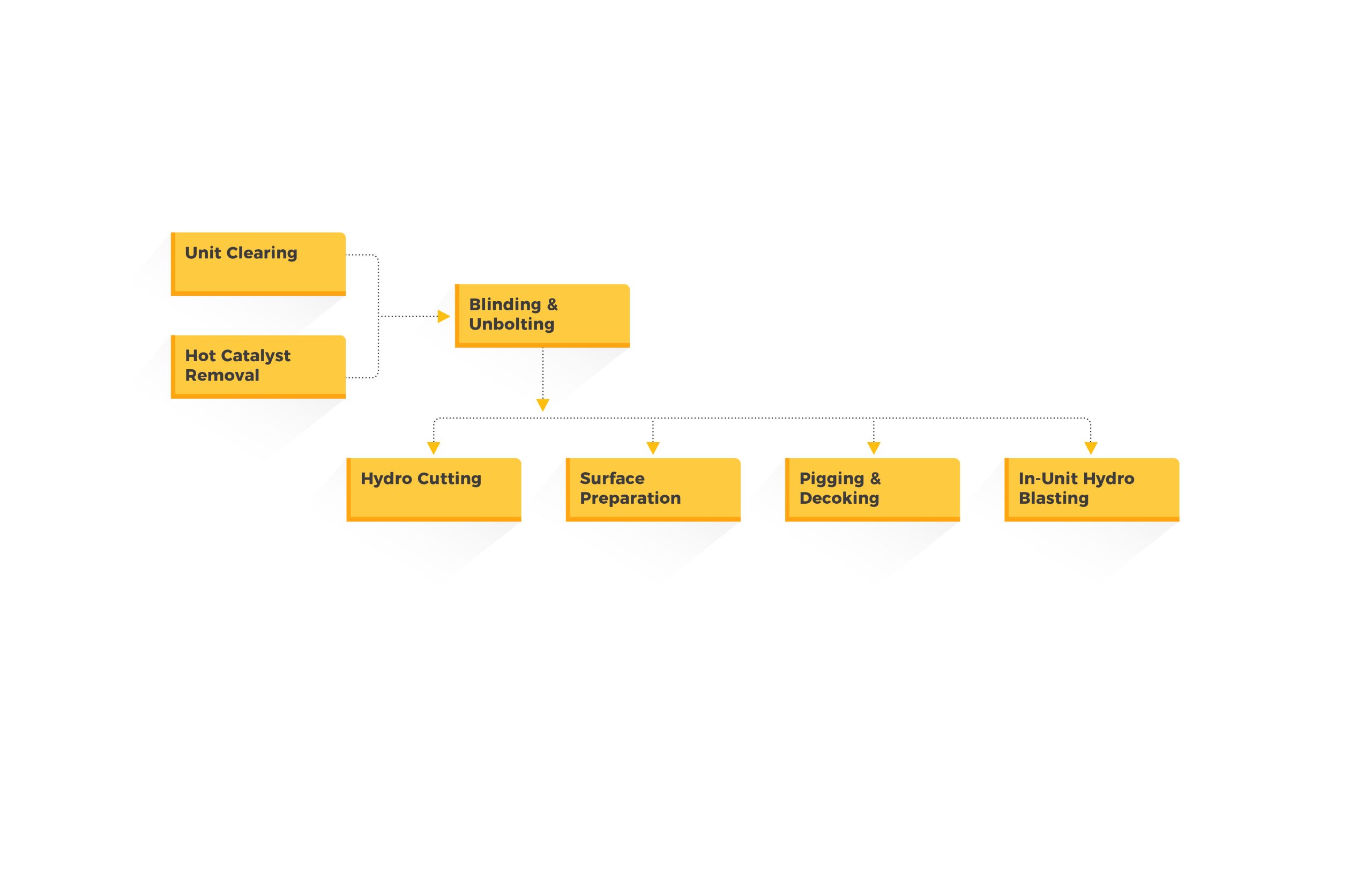

FCCU Turnaround Capabilities

Specialty Service Highlights

Our turnkey, multi-service line solutions for FCCU turnarounds include these advanced technologies.

Unit Clearing

A turnkey FCCU decontamination package using safe and effective cleaning products, experienced technical supervision, advanced equipment and innovative processes.

Opens the unit efficiently, saving days on the turnaround critical path

Safe for personnel and equipment

Pre-engineering to develop detail drawings and timelines

Proven, predictable results

Hot Catalyst Removal

Save days on your FCCU turnaround and reduce the critical path by removing residual catalyst during unit shutdown.

1,250°F (677°C) vacuum technology

Eliminates cooling time

Savings on catalyst purchase and disposal

Operational yield support, transloading

Hydro Cutting

The safe, precise solution for reactor and regenerator head removal, riser line cuts, and more.

40,000 psi water

Fully automated operation

Specialty tracks

Dedicated hydro cutting teams

Hydro Blasting

The latest automated technology and equipment for fast, effective tube and shell-side cleaning.

Units up to 40,000 psi

In unit and pad

Automated technology

lab management